ROEQ Top Modules

Get the most out of your MiR AMRs

ROEQ designs, develops and manufactures standard robotic equipment that helps you get the most out of your MiR autonomous mobile robots (AMR). Whether you need to pick up /drop off carts, racks, pallets etc or transfer loads to conveyor stations, the ROEQ range with ROEQ Assist software provide safe, reliable solutions.

For a full, reliable and safe solution, your AMR must work seamlessly together with the surrounding equipment. Your MiR AMR can be programmed to safely move around the production or warehouse floor. However, in order to pick up, drop off or transfer loads to different stations, you will need a ROEQ top module + relevant equipment such as ROEQ carts, docking stations and optional accessories such as forks (for lifting pallets). The ROEQ software (ROEQ Assist) ensures a smooth integration with the MiR robot. It sets the robot footprint e.g. if a cart is attached or not, and chooses the right ROEQ safety zone – which is also provided by ROEQ to fit the solution. ROEQ Assist also generates MiR missions to get you up and running quickly. In this way ROEQ Robotic Equipment can unleash the full potential of your AMR.

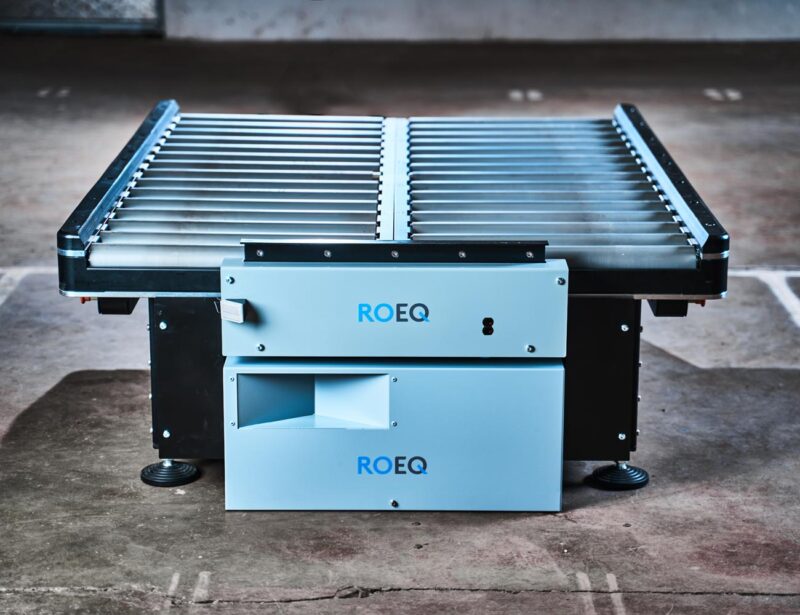

Top Modules

All ROEQ top modules come with ROEQ Assist software that includes setups tools, making it easy for you to quickly get your solution up and running. The software creates missions, sets the robot footprint, and choses the right ROEQ safety zones. ROEQ Assist is fully compatible with MiR software and ensures consistency throughout the installation.

There are three types: Roller Modules, Lifter Modules and Cart & Rack Modules.

- Roller Modules are for conveyor solutions. These roller modules have been developed to optimise safety and efficiency when transporting and transferring goods to and from conveyors. They have three types of sensors, and the rollers are braked during transport to ensure the safety and security of goods and people. For further safety, there are built-in barriers to protect fingers from being caught in the rollers.

- Lifter Modules lift, transport and drop off pallets, crates and racks, as well as shelf carts. A versatile solution for transporting different types of loads with only small adjustments.

- Cart & Rack Modules provide a safe, reliable and versatile solution for transporting cargo between work stations.

GuardCom

The ROEQ GuardCom System is a wireless data communication technology that allows reliable and stable communication between ROEQ top modules and stationary conveyor stations. Unlike traditional WiFi connections, the ROEQ GuardCom System uses robust sensor technology to ensure quick and safe communication without any potential instabilities.